COMPANY NEWS

《 BACK LIST

Swiss-type lathes and Swiss-type lathe inserts

What is a Swiss-type lathe?

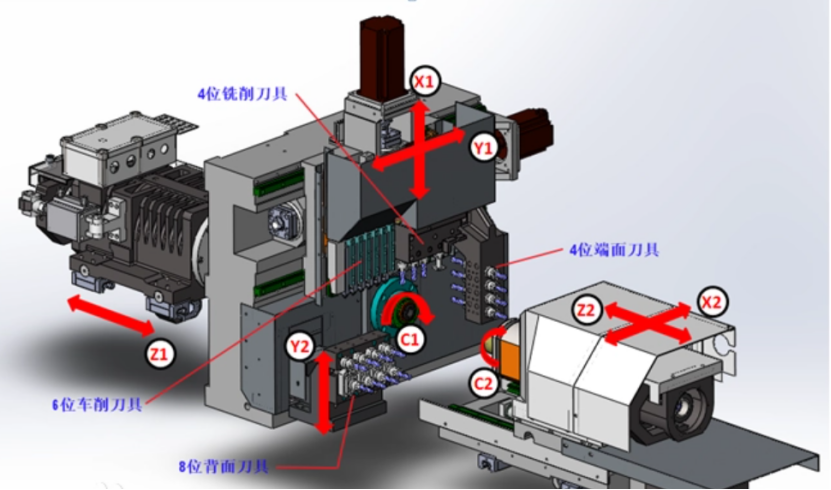

Swiss-type lathe is called Swiss-type CNC lathe. It is a precision processing equipment that can complete complex processing such as turning, milling, drilling, boring, tapping, and engraving at the same time. It is mainly used for batch processing of precision hardware and shaft-type non-standard parts.

This machine tool originated in Germany and Switzerland. In the early stage, it was mainly used for precision processing of military equipment. China's Swiss-type lathe manufacturing started late. Due to the closed technology and policy restrictions, China's Swiss-type lathes before the 1990s mainly relied on imports to meet processing needs. With the continuous development of automation and strong market demand, a large number of powerful CNC Swiss-type lathe manufacturers have emerged in the Chinese market. There are manufacturers of this series of machine tools in the Yangtze River Delta and the Pearl River Delta, and they have achieved good market applications, filling the domestic gap.

Since the Swiss-type lathe uses a double-axis arrangement tool, it greatly reduces the processing cycle time. It has a qualitative leap in processing efficiency and processing accuracy compared to CNC lathes, and is very suitable for mass production of precision shaft parts. The chip cutting tool has been processed at the clamping part of the spindle and the workpiece, ensuring the constant processing accuracy. The maximum processing diameter of the Swiss lathe on the market is 38mm, which has great advantages in the precision shaft processing market. This series of machine tools realizes the fully automated production of a single machine tool, reducing labor costs and product defective rates.

Features of Swiss lathe tools

The characteristics of Swiss lathe programming tools mainly include high precision, high efficiency, suitable for small diameter deep hole processing, and good wear resistance and adaptability.

Swiss lathe tools are usually suitable for processing holes with small diameters and large depths, and must be able to withstand high-speed rotation and cutting loads. Swiss lathe programming tools are widely used in the field of precision machining.

The materials of Swiss lathe programming tools usually include high-speed steel, cemented carbide, ceramics and other alloy materials. These materials are characterized by high hardness, high strength and good wear resistance, can adapt to different cutting speeds and processing conditions, and extend the service life of the tool.

When programming Swiss lathes, optimizing the tool path and parameter settings are the key. Reasonable program design can avoid unnecessary tool load, reduce wear, and ensure machining accuracy.

Swiss-type programming tools are widely used in industries that require precision internal hole machining, such as automobile manufacturing, mold industry, medical equipment, and military industry.

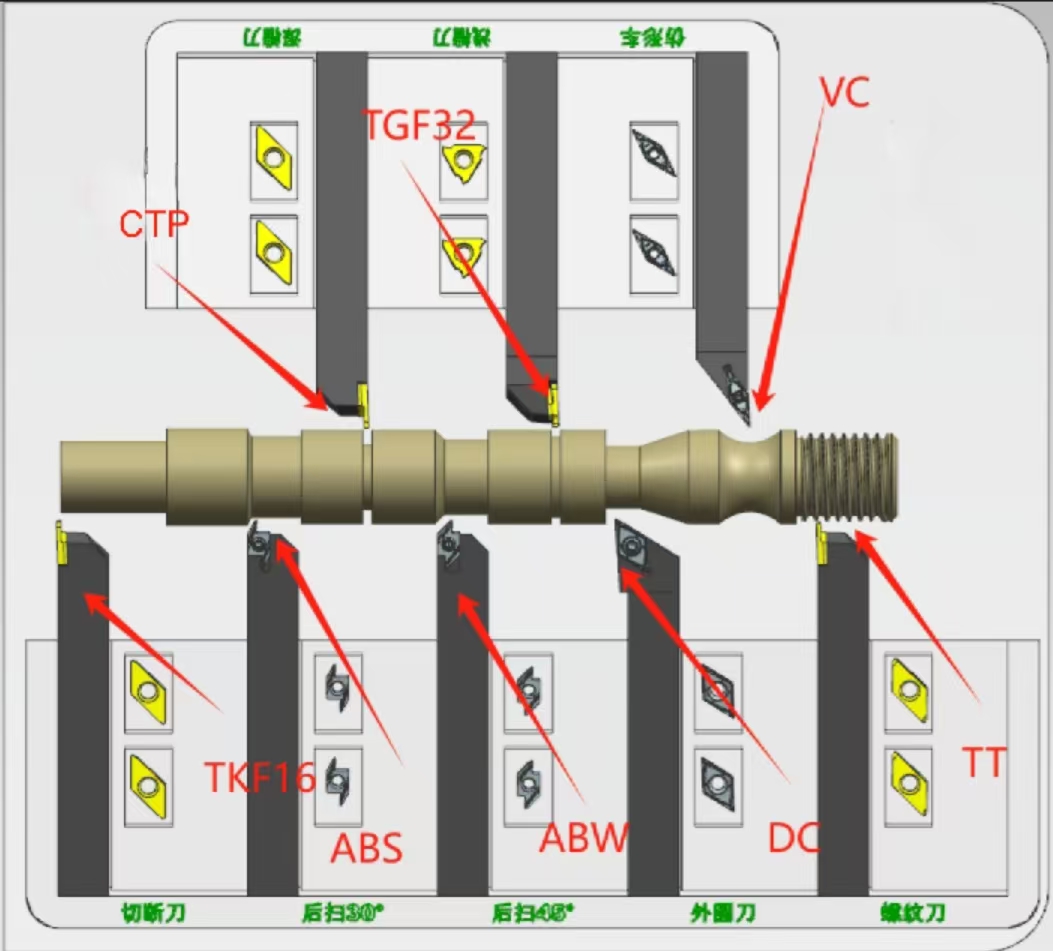

Shenzhen Yiteng Cutting Tools Co.,Ltd is a professional swiss lathe inserts manufacturer, including ABS15R series,TGF32 series, DCGT11T series,TNGG1604 series and VBGT1103 series.