COMPANY NEWS

《 BACK LIST

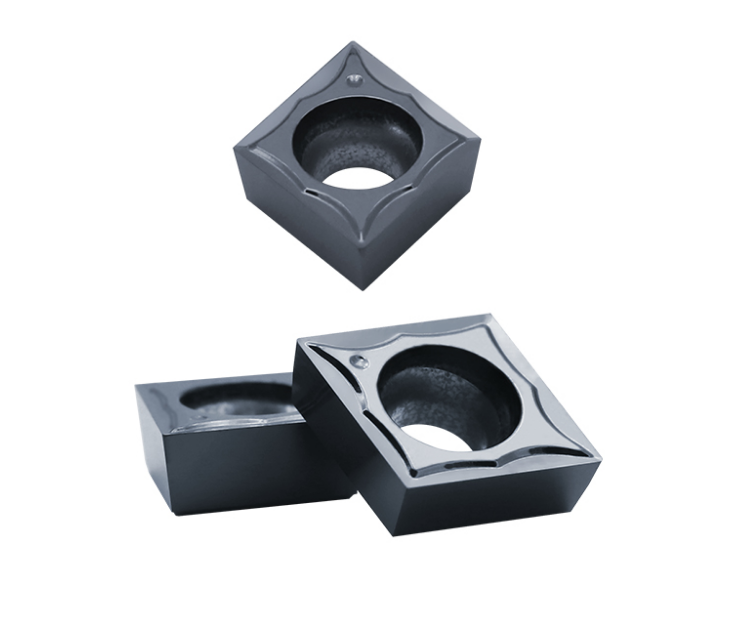

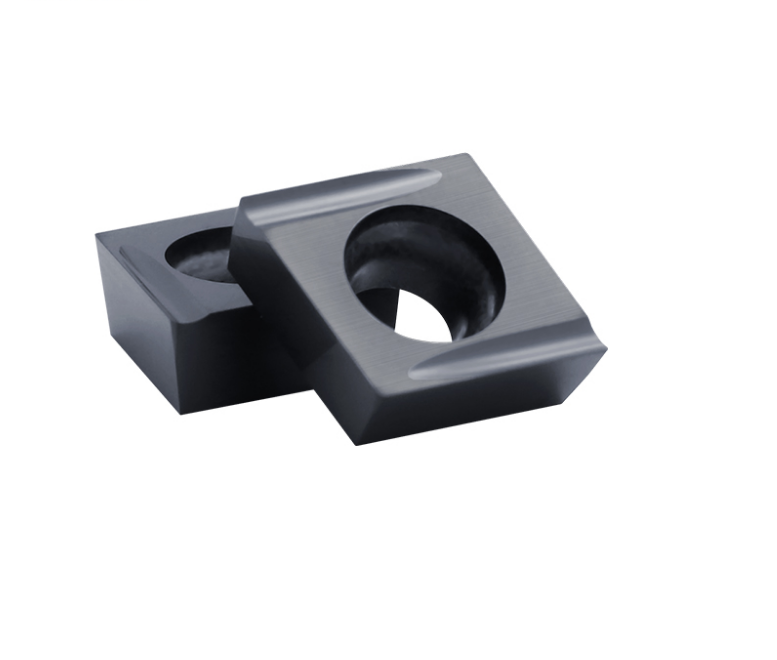

Explore the relationship between the size of the back angle and the life of the insert

When cutting with a carbide insert, if the front angle of the standard turning tool is made larger, it will soon be found that the cutting edge becomes blunt and the surface roughness of the machined surface increases. If not only the front angle is made larger, but also the back angle is made larger, the problem will be solved.

The size of the front angle of the carbide insert will affect the change of cutting resistance, and it will also affect the generation of cutting heat. When the front angle becomes larger, the cutting heat decreases, and when it becomes smaller, the cutting heat increases. When processing aluminum parts, since aluminum castings are particularly susceptible to cutting heat, in this case, in order to avoid the generation of built-up edge and bonding, you can choose a very fast cutting speed, or increase the front angle and back angle, so that the probability of heat generation and bonding can be greatly reduced.

Shenzhen Yi Teng Cutting Tool Co.,Ltd. is a professional cnc cutting tools manufacturer, mainly producing tungsten carbide inserts, Swiss lathe inserts, external tool holders, internal tool holders, boring bars, milling cutters,etc. We have a self-created brand, EATH TOOLS, which receives a good reputation in the industry.We devote ourselves to provide perfect cutting tools solutions for customers.