Producteigenschap:

1. 100% original carbide powder and excellent wear resistance and toughness;

2. Hoge prestaties van CVD/PVD-coating, met superhard en glad oppervlak;

3. ISO9001:2015 quality system control;

4. Professioneel spaanbrekerontwerp en biedt perfecte snijprestaties;

5. Nauwkeurige afmeting, hoge kwaliteit, concurrerende prijs;

6.Super lange levensduur van het gereedschap;

7. Aangepast inzetstukontwerp, coating, markering, verpakking zijn beschikbaar.

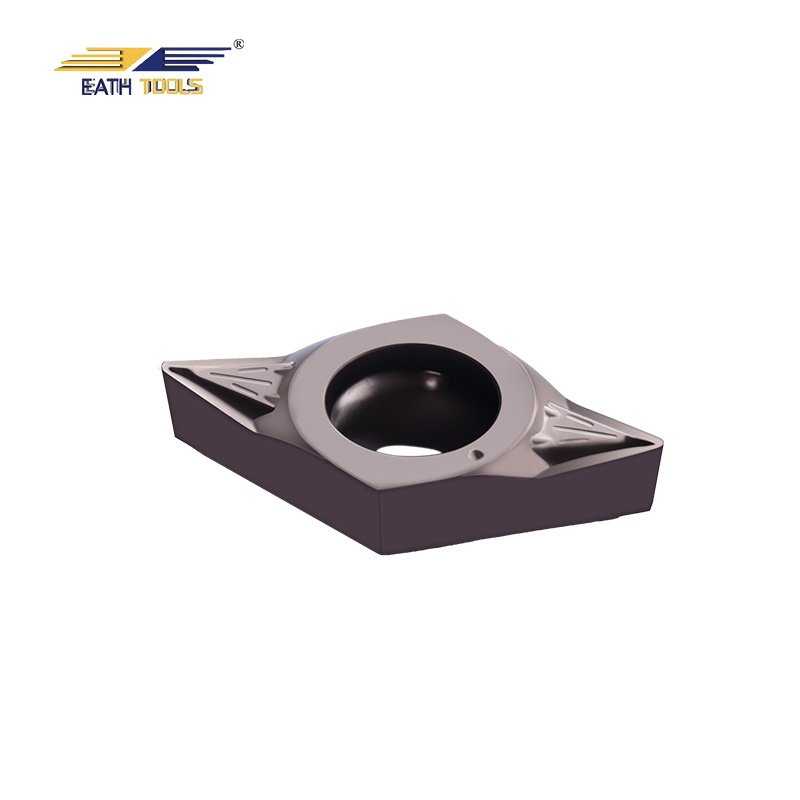

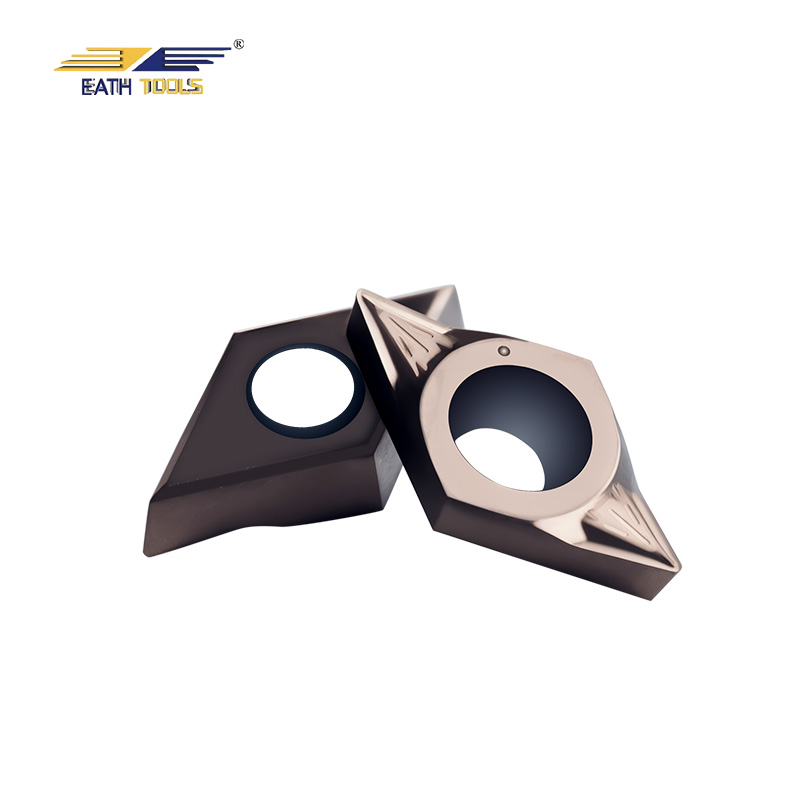

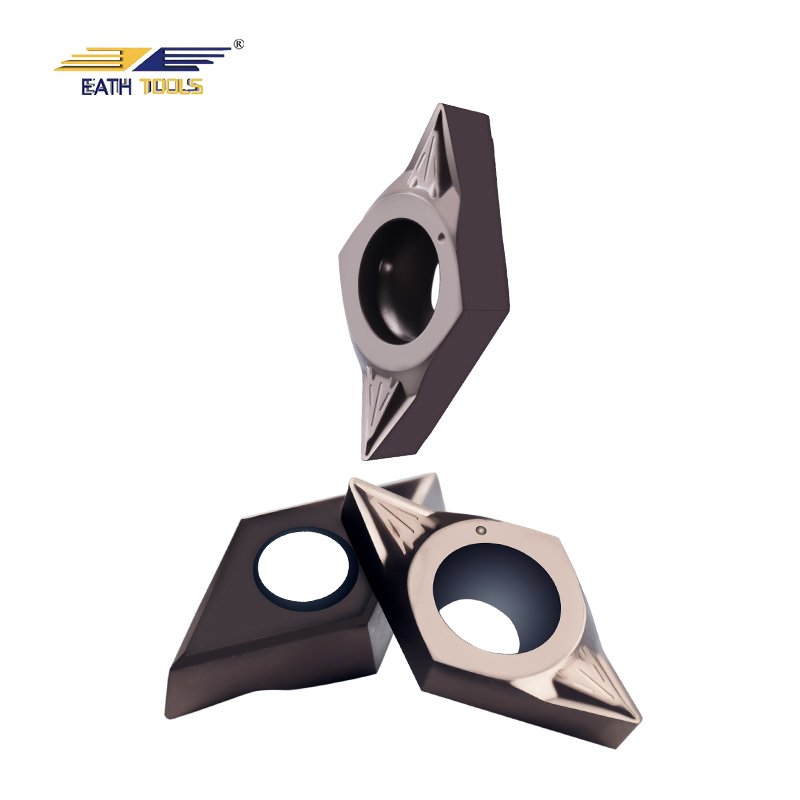

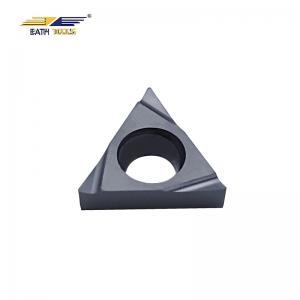

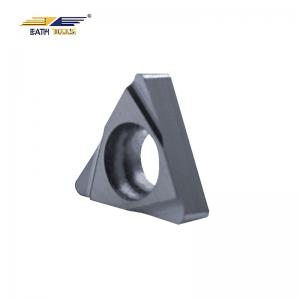

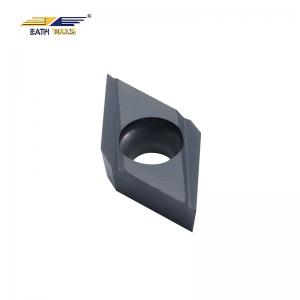

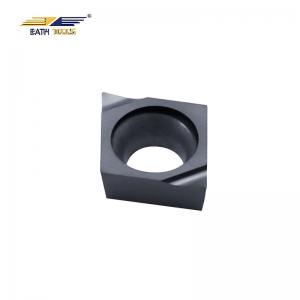

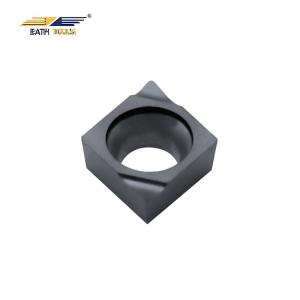

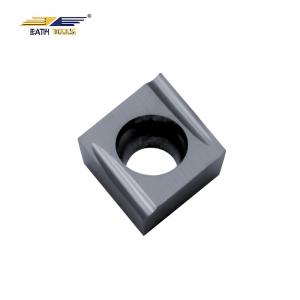

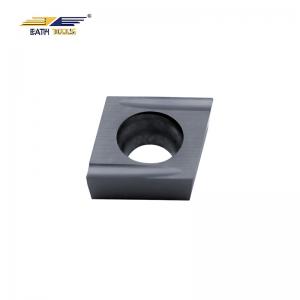

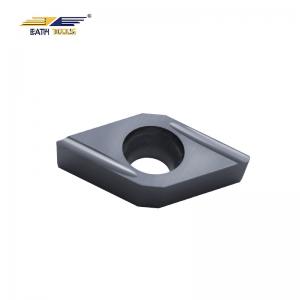

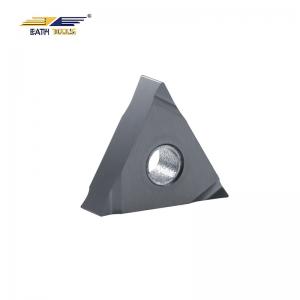

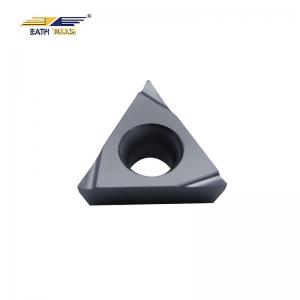

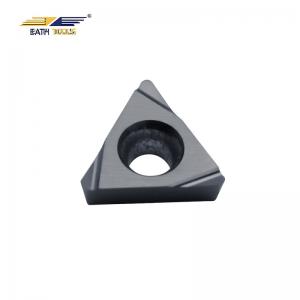

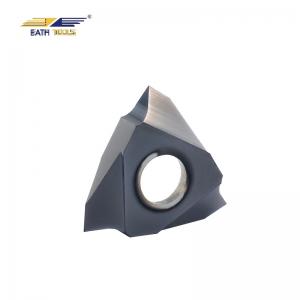

Product feature:

1. 100% original carbide powder and excellent wear resistance and toughness;

2. High performance of CVD/PVD coating, with super hard and smooth surface;

3. ISO9001:2015 quality system control;

4. Professional chip-breaker design and provides perfect cutting performance;

5. Precise dimension, high quality, competitive price;

6 . Super long tool service life;

7. Customized insert design, coating, marking, and packing are available.

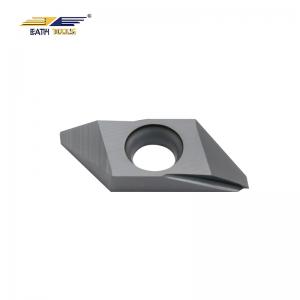

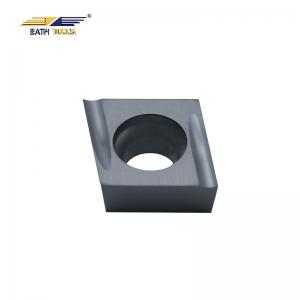

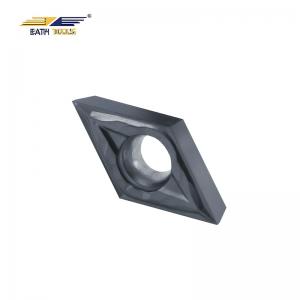

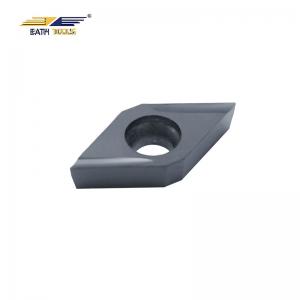

| Type | Edge Length (mm) | Insert Dimensions (mm) | Angle | Chip Breaker | |||

| IC | S | D | R | ||||

| DCGT070201-GQ | 07 | 6.35 | 2.38 | 2.8 | 0.1 | 7° | GQ |

| DCGT070201R-U | 07 | 6.35 | 2.38 | 2.8 | 0.1 | 7° | R-U |

| DCGT070202-GQ | 07 | 6.35 | 2.38 | 2.8 | 0.2 | 7° | GQ |

| DCGT070202R-U | 07 | 6.35 | 2.38 | 2.8 | 0.2 | 7° | R-U |

| DCGT070204-GQ | 07 | 6.35 | 2.38 | 2.8 | 0.4 | 7° | GQ |

| DCGTO70204R-U | 07 | 6.35 | 2.38 | 2.8 | 0.4 | 7° | R-U |

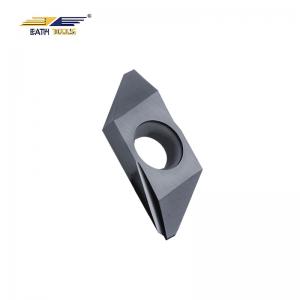

| DCGT11T301-AK | 11 | 9.525 | 3.97 | 4.4 | 0.1 | 7° | AK |

| DCGT11T301-CK | 11 | 9.525 | 3.97 | 4.4 | 0.1 | 7° | CK |

| DCGT11T301-GQ | 11 | 9.525 | 3.97 | 4.4 | 0.1 | 7° | GQ |

| DCGT11T301R-J | 11 | 9.525 | 3.97 | 4.4 | 0.1 | 7° | R-J |

| DCGT11T301R-U | 11 | 9.525 | 3.97 | 4.4 | 0.1 | 7° | R-U |

| DCGT11T301-YL | 11 | 9.525 | 3.97 | 4.4 | 0.1 | 7° | YL |

| DCGT11T302-AK | 11 | 9.525 | 3.97 | 4.4 | 0.2 | 7° | AK |

| DCGT11T302-GQ | 11 | 9.525 | 3.97 | 4.4 | 0.2 | 7° | GQ |

| DCGT11T302R-U | 11 | 9.525 | 3.97 | 4.4 | 0.2 | 7° | R-U |

| DCGT11T302R-J | 11 | 9.525 | 3.97 | 4.4 | 0.2 | 7° | R-J |

| DCGT11T304-GQ | 11 | 9.525 | 3.97 | 4.4 | 0.4 | 7° | GQ |

| DCGT11T304R-J | 11 | 9.525 | 3.97 | 4.4 | 0.4 | 7° | R-J |

| DCGT11T304R-U | 11 | 9.525 | 3.97 | 4.4 | 0.4 | 7° | R-U |

| DCGT11T301-AS | 11 | 9.525 | 3.97 | 4.4 | 0.1 | 7° | AS |

| DCGT11T302-AS | 11 | 9.525 | 3.97 | 4.4 | 0.2 | 7° | AS |

| DCGT11T304-AS | 11 | 9.525 | 3.97 | 4.4 | 0.4 | 7° | AS |

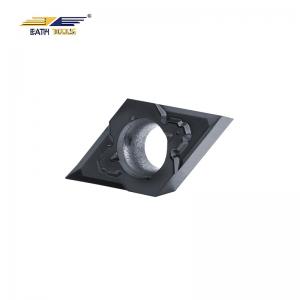

Precautions for use:

1. Choose the appropriate blade based on the type of material being processed.

2. Select the appropriate insert material and geometry based on cutting conditions.

3. Choose a blade with good rigidity and thermal stability.

4. The geometry of the insert has an important influence on the cutting effect and cutting quality.

5. Blade coating can improve the hardness, wear resistance, and thermal.

Fabrieksrondleiding

FAQ:

1. Wat zijn uw belangrijkste producten?

Eath Tools produceert voornamelijk externe draaigereedschapschachten, interne draaigereedschapschachten, freesschijven, groef- en draadsnijgereedschapschachten, wolfraamcarbide wisselplaten en klein gereedschap.

2. Hoe zit het met de levertijd?

Meestal hebben wij voorraad voor standaard maten, indien niet op voorraad is onze levertijd binnen 15 dagen.

3. Bent u een handelsonderneming of een fabriek?

Wij zijn al meer dan 15 jaar een professionele fabrikant.

__________________________________________________________________________________________________________________________________

Shenzhen Yiteng Snijgereedschappen Co., Ltd.

Adres: Gebouw 5, Baohu Industrial Park, Guangpei-gemeenschap, Guanlan Street, Longhua District, Shenzhen City, provincie Guangdong, China

Phone:+86 138 7415 0655

E-mail:[email protected]

Whatsapp/Wechat:+86 138 7415 0655