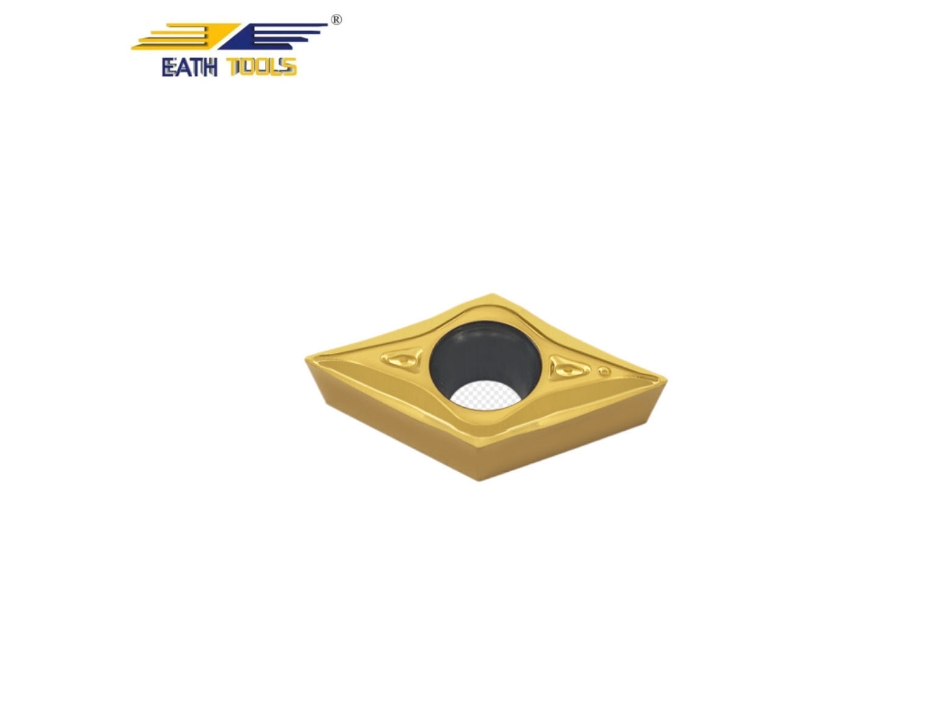

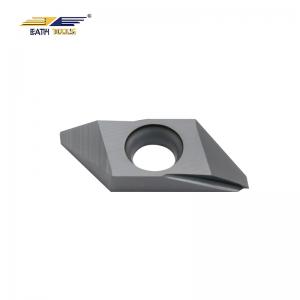

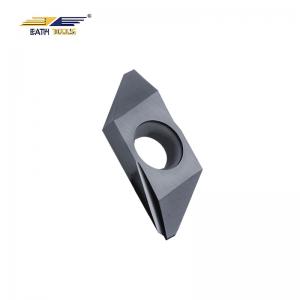

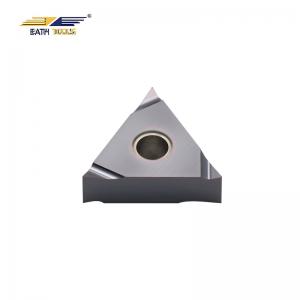

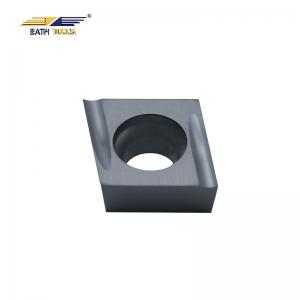

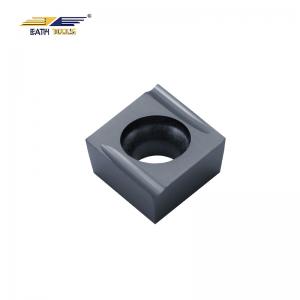

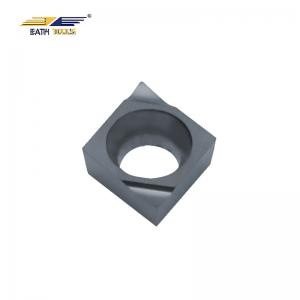

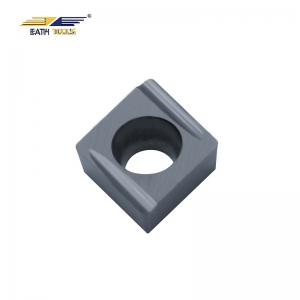

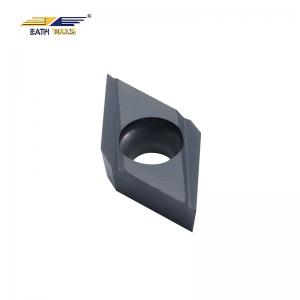

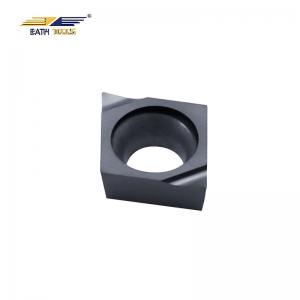

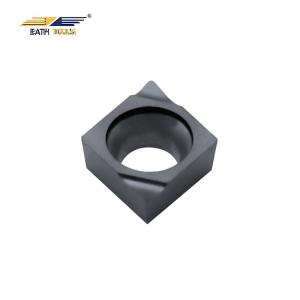

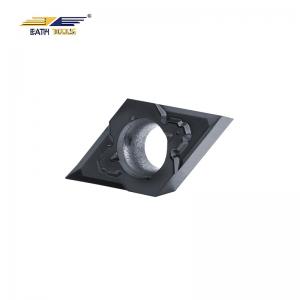

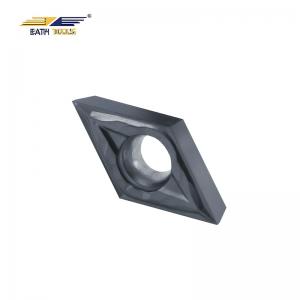

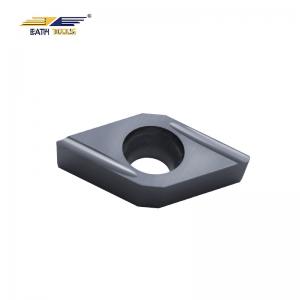

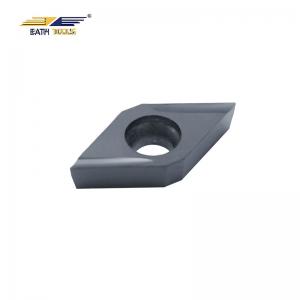

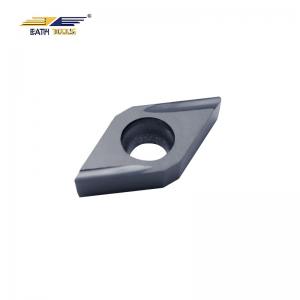

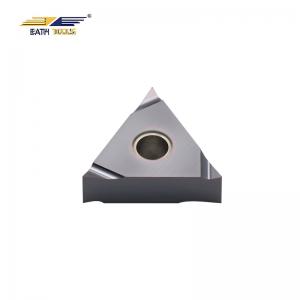

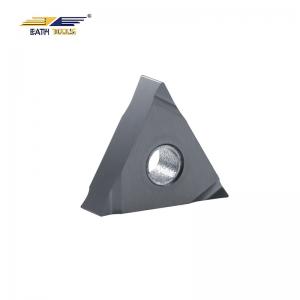

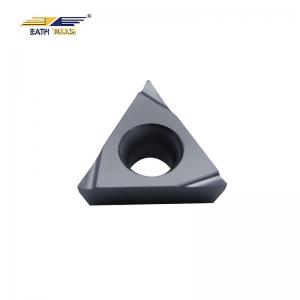

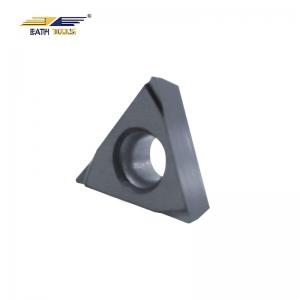

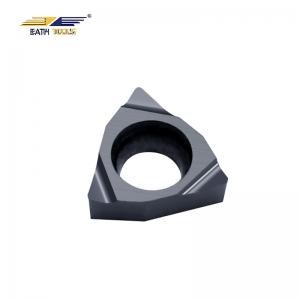

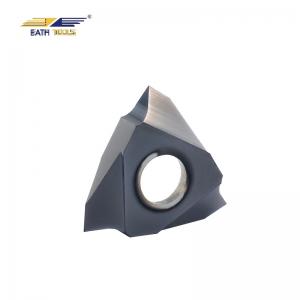

Product feature:

1. 100% original carbide powder and excellent wear resistance and toughness;

2. High performance of CVD/PVD coating, with super hard and smooth surface;

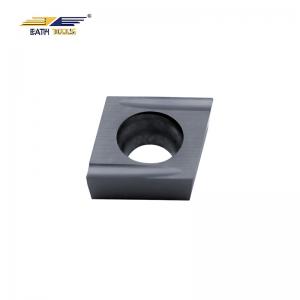

3. ISO9001:2015 quality system control;

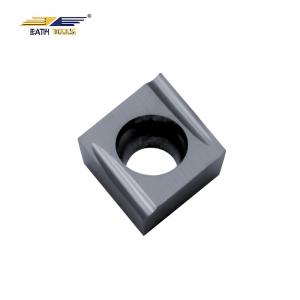

4. Professional chip-breaker design and provides perfect cutting performance;

5. Precise dimension, high quality,competitive price;

6.Super long tool service life;

7. Customized insert design, coating, marking, packing are available.

| Type | Edge Length (mm) | Insert Dimensions (mm) | Angle | Chip Breaker | |||

| IC | S | D | R | ||||

| DCGT070201-GQ | 07 | 6.35 | 2.38 | 2.8 | 0.1 | 7° | GQ |

| DCGT070201R-U | 07 | 6.35 | 2.38 | 2.8 | 0.1 | 7° | R-U |

| DCGT070202-GQ | 07 | 6.35 | 2.38 | 2.8 | 0.2 | 7° | GQ |

| DCGT070202R-U | 07 | 6.35 | 2.38 | 2.8 | 0.2 | 7° | R-U |

| DCGT070204-GQ | 07 | 6.35 | 2.38 | 2.8 | 0.4 | 7° | GQ |

| DCGTO70204R-U | 07 | 6.35 | 2.38 | 2.8 | 0.4 | 7° | R-U |

| DCGT11T301-AK | 11 | 9.525 | 3.97 | 4.4 | 0.1 | 7° | AK |

| DCGT11T301-CK | 11 | 9.525 | 3.97 | 4.4 | 0.1 | 7° | CK |

| DCGT11T301-GQ | 11 | 9.525 | 3.97 | 4.4 | 0.1 | 7° | GQ |

| DCGT11T301R-J | 11 | 9.525 | 3.97 | 4.4 | 0.1 | 7° | R-J |

| DCGT11T301R-U | 11 | 9.525 | 3.97 | 4.4 | 0.1 | 7° | R-U |

| DCGT11T301-YL | 11 | 9.525 | 3.97 | 4.4 | 0.1 | 7° | YL |

| DCGT11T302-AK | 11 | 9.525 | 3.97 | 4.4 | 0.2 | 7° | AK |

| DCGT11T302-GQ | 11 | 9.525 | 3.97 | 4.4 | 0.2 | 7° | GQ |

| DCGT11T302R-U | 11 | 9.525 | 3.97 | 4.4 | 0.2 | 7° | R-U |

| DCGT11T302R-J | 11 | 9.525 | 3.97 | 4.4 | 0.2 | 7° | R-J |

| DCGT11T304-GQ | 11 | 9.525 | 3.97 | 4.4 | 0.4 | 7° | GQ |

| DCGT11T304R-J | 11 | 9.525 | 3.97 | 4.4 | 0.4 | 7° | R-J |

| DCGT11T304R-U | 11 | 9.525 | 3.97 | 4.4 | 0.4 | 7° | R-U |

| DCGT11T304R-YL | 11 | 9.525 | 3.97 | 4.4 | 0.4 | 7° | R-YL |

Precautions for use:

1. Choose the appropriate insert based on the type of material being processed.

2. Select the appropriate insert material and insert geometry based on cutting conditions.

3. Choose an insert with good rigidity and thermal stability.

4. The geometry of the insert has an important influence on the cutting effect and cutting quality.

5. Insert coating can improve the hardness, wear resistance, and thermal stability of the insert, extending the service lifetime of the insert.

Factory Tour

FAQ:

1. What are your main products?

Eath Tools mainly manufactures external turning tool shanks, internal turning tool shanks, milling cutter discs, grooving &threading tool shanks, tungsten carbide inserts, and small tools.

2. How about the delivery time?

Usually, we have stock for standard sizes, if no stock, our delivery time is within 15 days.

3. Are you a trading company or a factory?

We are a professional manufacturer for over 15 years.

_____________________________________________________________________________________________________________________

Shenzhen Yi Teng Cutting Tool Co., Ltd.

Address: Building 5, Baohu Industrial Park, Guangpei Community, Guanlan Street, Longhua District, Shenzhen City, Guangdong Province, China

Phone:+86 181 1879 8239

Email:info@eathtools.com

Whatsapp/Wechat:+86 181 1879 8239