COMPANY NEWS

《 BACK LIST

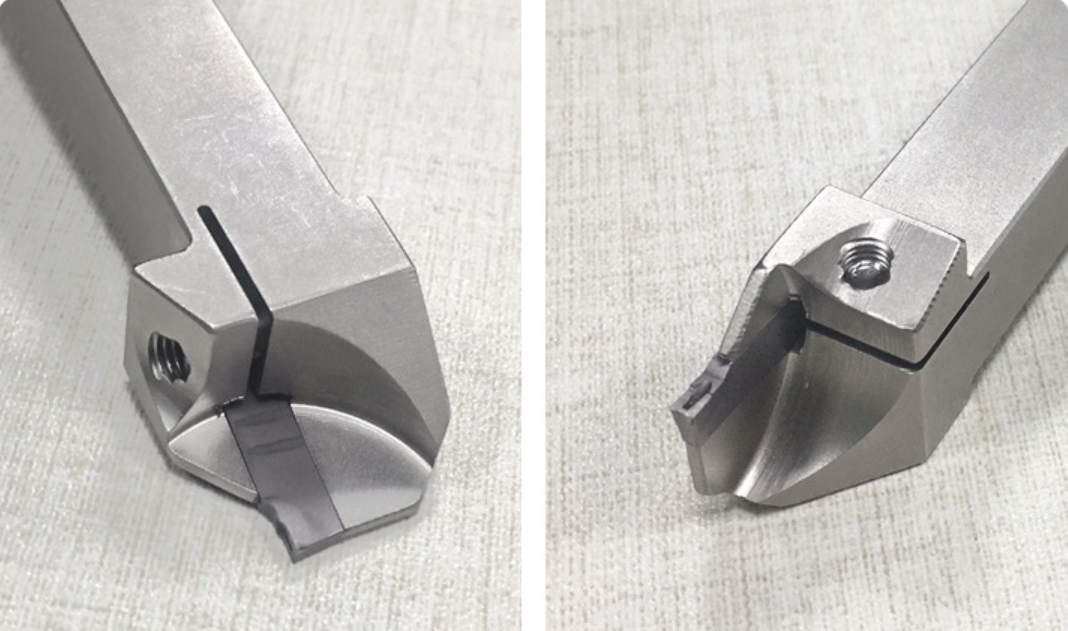

Nzira yekusarudza chekucheka uye grooving tool

Zvishandiso zvekuchekwa uye grooving zvakakamurwa kuva marudzi maviri: kucheka-kubvisa uye grooving zvishandiso. Chishandiso chekucheka-cheka chine blade refu uye blade nhete. Chinangwa chekugadzirwa uku ndechekuderedza kushandiswa kwezvinhu zvebasa rekushanda uye kuvimbisa kuti nzvimbo yacho inogona kutemwa kana uchicheka.Maitiro ekusarudza akakodzera kucheka-kubvisa uye grooving tool inogona kuonekwa kubva pane zvinotevera.

1. Ziva rudzi rwegorofu

Kune matatu akakosha magirovha emhando yekucheka-kubvisa uye grooving maturusi, ayo ari ekunze grooves, yemukati grooves uye yekupedzisira grooves. Migero yekunze ndiyo iri nyore kugadzirisa nekuti giravhiti uye inotonhorera inogona kubatsira kubvisa chip. Uye zvakare, ekunze groove processing inoonekwa kune anoshanda, uye mhando yekugadzira inogona kutariswa zvakananga uye zviri nyore. Asi zvimwe zvipingamupinyi zvinogona kuitika mukugadzira dhizaini kana clamping zvinofanirwa kudzivirirwa. Kazhinji kutaura, iyo yekucheka mhedzisiro ndiyo yakanyanya kunaka kana iyo muromo weiyo grooving chishandiso ichichengetwa zvishoma pazasi pepakati mutsara.

Internal hole grooving yakafanana neyekunze dhayamita grooving, kunze kwekuti kushandiswa kwekutonhodza uye kubvisa chip kunonetsa. Kune yemukati gomba grooving, kuita kwakanakisa kunowanikwa kana muromo uri pamusoro pepakati mutsara. Kugadzirisa iyo yekupedzisira kumeso groove, chishandiso chinofanirwa kufamba munzira yeaxial, uye radius yekuseri kwechiso chechishandiso inofanirwa kuenderana neradius yenzvimbo yakashongedzwa. Iyo machining mhedzisiro ndiyo yakanakisa kana iyo yekupedzisira yakatarisana ne grooving chishandiso yakakwira zvishoma pane yepakati mutsara.

2. Machine tool design uye unyanzvi hwemamiriro ezvinhu

Mukugadzira grooving, iyo dhizaini mhando uye tekinoroji mamiriro emuchina chishandiso zvakare zvinhu zvakakosha zvinoda kutariswa.

Zvimwe zvezvinonyanya kuita zvinodiwa zvemuchina wekushandisa zvinosanganisira: simba rakakwana rekuona kuti chishandiso chinomhanya mukati mekumhanya kwakaringana pasina kumira kana kuzununguka; kuomarara kwakakwana kupedzisa chirongwa chekucheka chinodiwa pasina kutaura; yakakwana inotonhorera kumanikidza uye kuyerera kubatsira chip kubviswa; yakakwana inotonhorera kumanikidza uye kuyerera kubatsira chip kubviswa; kukwana kwakakwana. Uye zvakare, zvakakoshawo kugadzirisa nemazvo uye kugadzirisa chishandiso chemuchina kuitira kugadzirisa iyo chaiyo groove chimiro uye saizi.

3. Nzwisisa maitiro eiyo workpiece zvinhu

Kuziva humwe hunhu hwechishandiso (senge kusimba kwesimba, hunhu hwekuomesa basa uye kuoma) kwakakosha kuti unzwisise mabatiro anoita chishandiso.

Paunenge uchigadzira zvakasiyana-siyana zvekushandisa, zvinodikanwa kushandisa kukurumidza kucheka uye chimiro mamita kudzora machipisi, kana kushandisa yakakosha mafiriza metres kuwedzera hupenyu hwechishandiso.

Mukupfupisa, kusarudzwa kwakarurama uye kushandiswa kwezvishandiso zvekucheka kuchasarudza mari-inobudirira yekugadzirisa. Grooving zvishandiso zvinogona kugadzira workpiece geometry nenzira mbiri: imwe ndeyekuburitsa iyo yese groove chimiro kuburikidza nekucheka kumwe; imwe yacho ndeyekuita rough saizi yekupedzisira yegroove mumatanho kuburikidza nekucheka kwakawanda. Mushure mekusarudza chishandiso geometry, unogona kufunga nezve kushandisa maturusi machira anogona kuvandudza chip evacuation performance.