Karolo ea sehlahisoa:

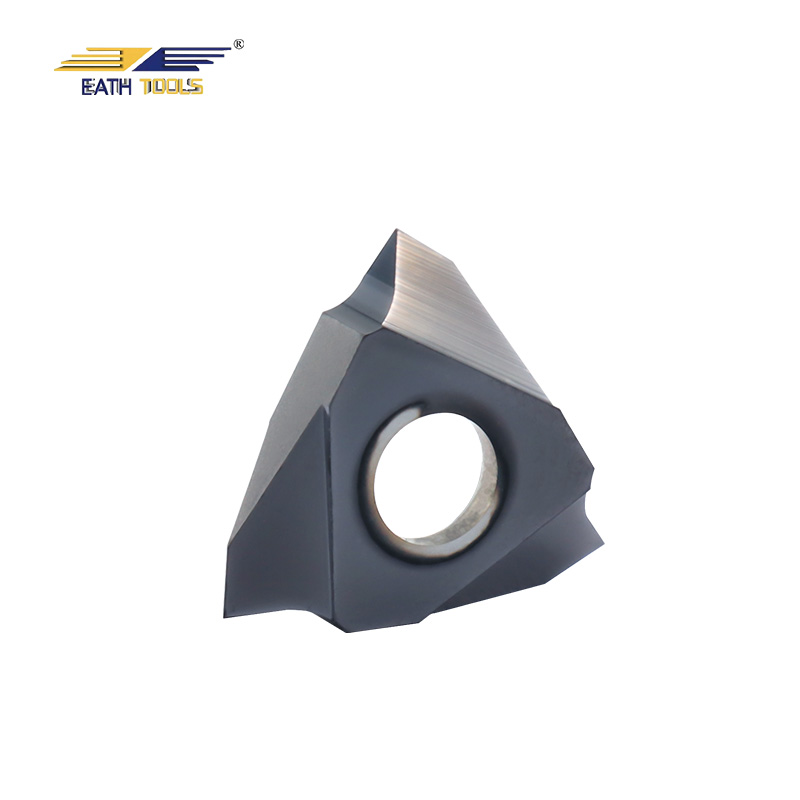

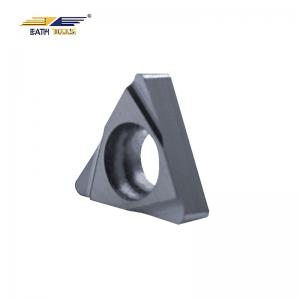

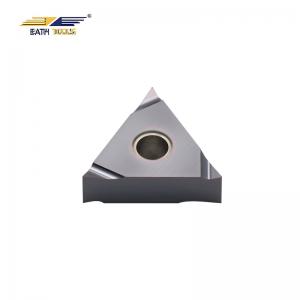

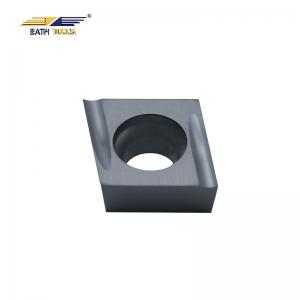

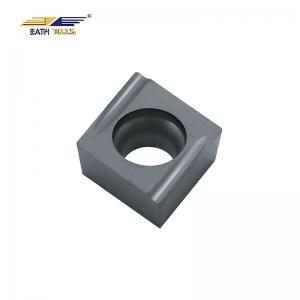

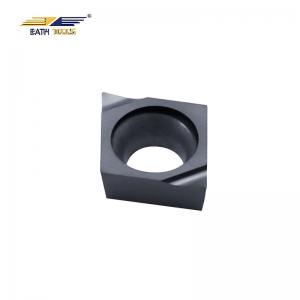

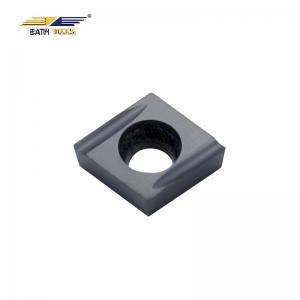

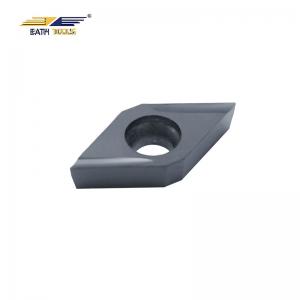

1. 100% original carbide powder and excellent wear resistance and toughness;

2. Ts'ebetso e phahameng ea ho roala CVD / PVD, e nang le sebaka se thata haholo le se boreleli;

3. ISO9001:2015 quality system control;

4. Moralo oa setsebi sa chip-breaker mme o fana ka ts'ebetso e phethahetseng ea ho itšeha;

5. Boemo bo nepahetseng, boleng bo holimo, theko ea tlholisano;

6.Bophelo ba tšebeletso ea nako e telele ea sesebelisoa;

7. Moralo o hlophisitsoeng oa ho kenya, ho roala, ho tšoaea, ho paka ho fumaneha.

Karolo ea sehlahisoa:

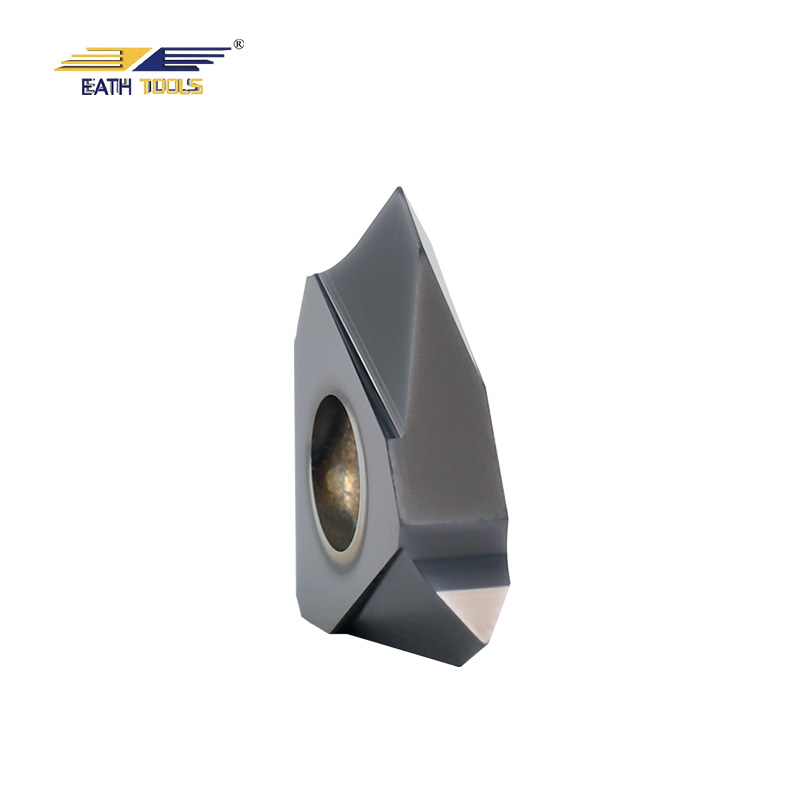

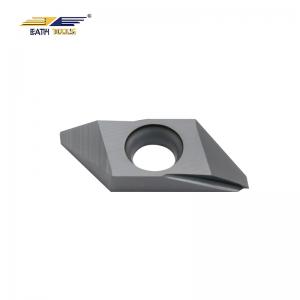

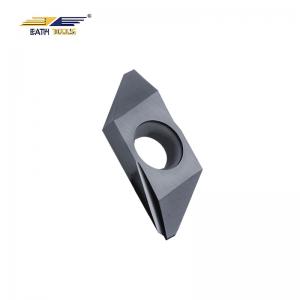

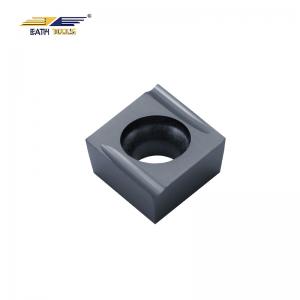

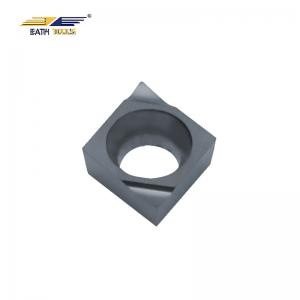

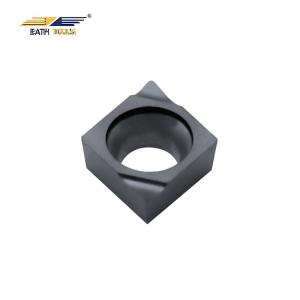

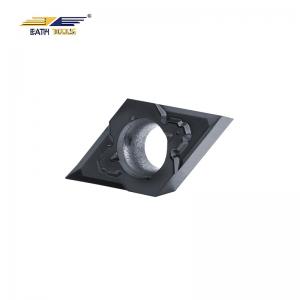

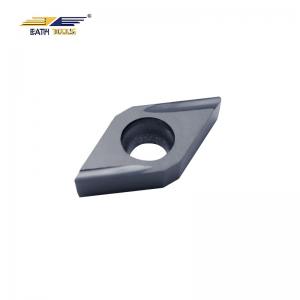

1. 100% original carbide powder and excellent wear resistance and toughness;

2. Ts'ebetso e phahameng ea CVD / PVD Coatings, e nang le bokaholimo bo thata le bo boreleli;

3. ISO9001:2015 quality system control;

4. Moralo oa boqapi bo brop-breaker mme o fana ka ts'ebetso e phethahetseng ea ho khaola;

5. Kakaretso ea boleng bo holimo, boleng bo phahameng, theko ea tlholisano;

6. Bophelo bo bolelele ba lisebelisoa tsa matla

7. Moralo o hlophisitsoeng, ho koahela, ho alosa, le ho paka se teng.

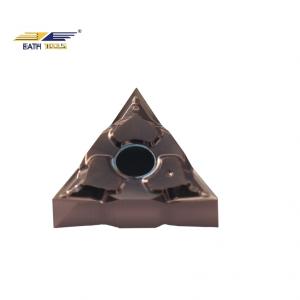

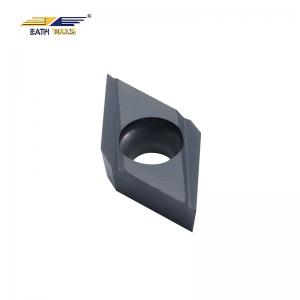

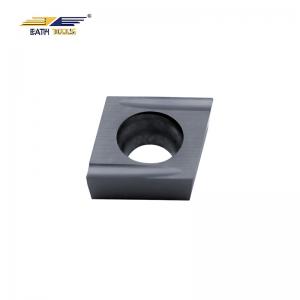

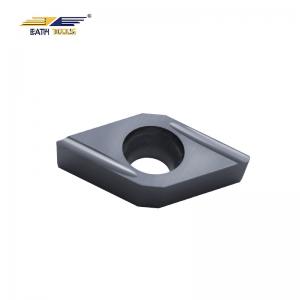

| Mofuta | Pitch (limim) | Kenya Maemo (MM) | Angle | Chip breaker | |||

| IC | S | D | R | ||||

| 16ER/L 050ISO | 0.5 | 9.525 | 3.68 | 4.0 | 0.06 | 60° | / |

| 16ER/L 075ISO | 0.75 | 9.525 | 3.68 | 4.0 | 0.09 | 60° | / |

| 16ER/L 100ISO | 1.0 | 9.525 | 3.68 | 4.0 | 0.12 | 60° | / |

| 16ER/L 125ISO | 1.25 | 9.525 | 3.68 | 4.0 | 0.15 | 60° | / |

| 16ER/L 150ISO | 1.5 | 9.525 | 3.68 | 4.0 | 0.19 | 60° | / |

| 16ER/L 175ISO | 1.75 | 9.525 | 3.68 | 4.0 | 0.22 | 60° | / |

| 16ER/L 200ISO | 2.0 | 9.525 | 3.68 | 4.0 | 0.25 | 60° | / |

| 16ER/L 250ISO | 2.5 | 9.525 | 3.68 | 4.0 | 0.32 | 60° | / |

| 22ER 300ISO | 3.0 | 12.7 | 4.9 | 4.85 | 0.41 | 60° | / |

| 22ER 350ISO | 3.5 | 12.7 | 4.9 | 4.85 | 0.48 | 60° | / |

| 22ER 400ISO | 4.0 | 12.7 | 4.9 | 4.85 | 0.55 | 60° | / |

| 22ER 450ISO | 4.5 | 12.7 | 4.9 | 4.85 | 0.62 | 60° | / |

| 22ER 500ISO | 5.0 | 12.7 | 4.9 | 4.85 | 0.70 | 60° | / |

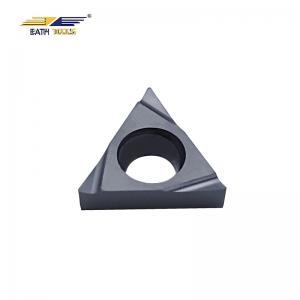

| TTX32R 6000 | 0.5-1.0 | 9.525 | 3.18 | 4.4 | 0.00 | 60° | / |

| TTX32R 6005 | 0.5-1.0 | 9.525 | 3.18 | 4.4 | 0.05 | 60° | / |

| TTX32R 6001 | 1.0-2.0 | 9.525 | 3.18 | 4.4 | 0.1 | 60° | / |

| TTX32R 6000S | 0.5- | 9.525 | 3.18 | 4.4 | 0 | 60° | / |

| TTX32R 6005S | 0.5- | 9.525 | 3.18 | 4.4 | 0.05 | 60° | / |

| TTX32R 5501 | _ | 9.525 | 3.18 | 4.4 | 0.1 | 55° | / |

| TTX32R 5501S | _ | 9.525 | 3.18 | 4.4 | 0.15 | 55° | / |

Litlhokahalo tsa Tšebeliso:

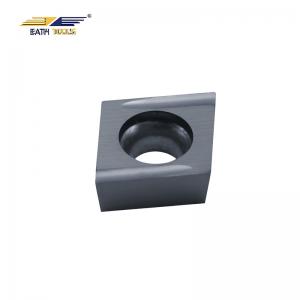

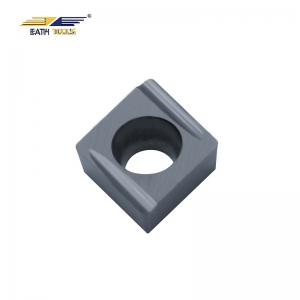

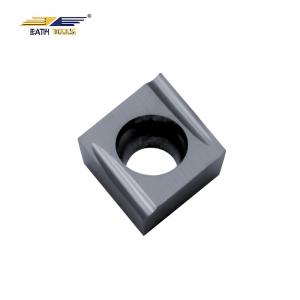

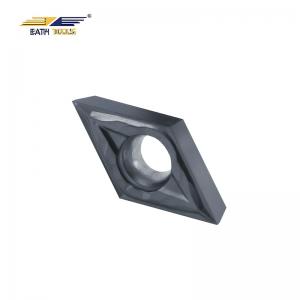

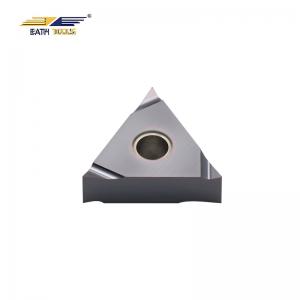

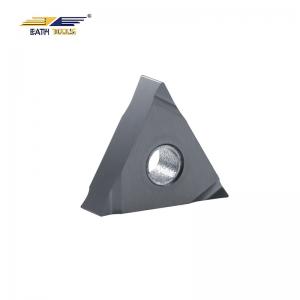

1. Khetha lehare le loketseng ho latela mofuta oa thepa e ntseng e sebetsoa.

2. Khetha boitsebiso bo loketseng le ho kenya geometry ho ipapisitse le maemo a sehiloeng.

3. Khetha lehare ka ho tsitsipana le ho tsilatsila le ho tsitsa.

4. Jimetry ea kenyelletso e na le tšusumetso ea bohlokoa molemong oa ho khaola le ho fokotsa boleng.

5. Blade Coating e ka ntlafatsa ho ba thata, roala khanyetso, le moferefere.

Leeto la Feme

LBH:

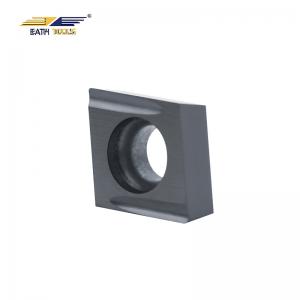

1. Lihlahisoa tsa hau tse ka sehloohong ke life?

Eath Tools haholo-holo e etsa lishanka tsa lisebelisoa tse fetolehang ka ntle, lishanka tsa lisebelisoa tsa ka hare, li-milling cutter discs, li-grooving & threading tool shanks, li-tungsten carbide inserts, le lisebelisoa tse nyenyane.

2. Ho thoe'ng ka nako ea ho pepa?

Hangata, re na le stock bakeng sa boholo bo tloaelehileng, haeba ho se na stock, nako ea rona ea ho fana e ka hare ho matsatsi a 15.

3. Na u k'hamphani ea khoebo kapa feme?

Re baetsi ba litsebi ka lilemo tse fetang 15.

____________________________________________________________________________________________________

Shenzhen Yiteng Cutting Tools Co., Ltd.

Aterese: Mohaho oa 5, Baohu Industrial Park, Sechaba sa Guangpei, Seterata sa Guanlan, Setereke sa Longhua, Motse oa Shenzhen, Profinseng ea Guangdong, China

Phone:+86 138 7415 0655

Email:info@eathtools.com

Whatsapp/Wechat:+86 138 7415 0655