NKHANI ZA COMPANY

《 BACK MTANDA

Momwe mungasankhire chida chodulira ndi kugwetsa

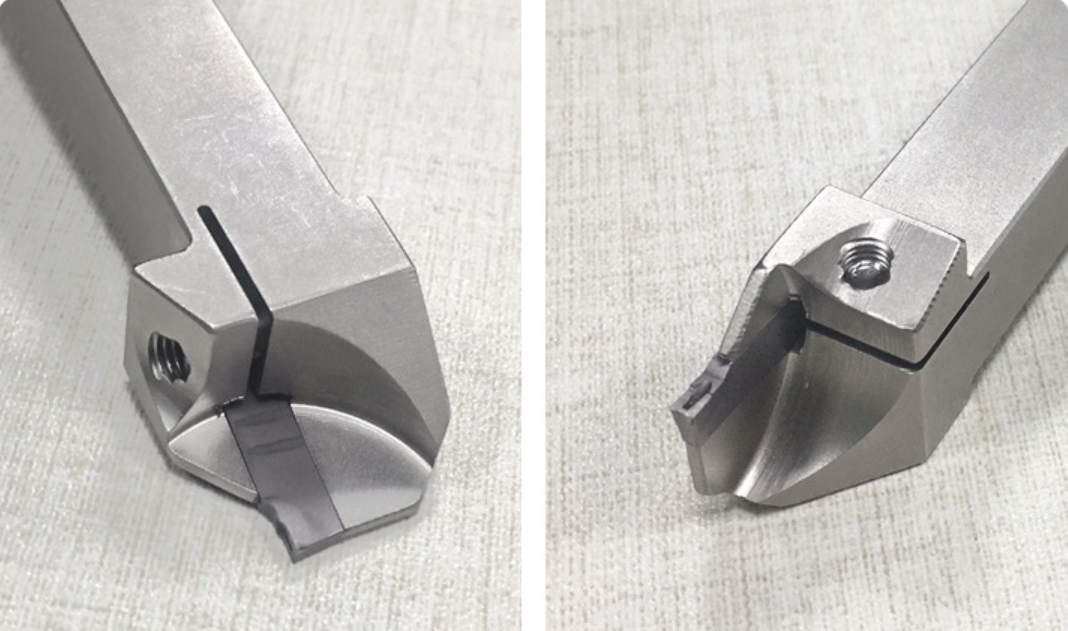

Zida zodulira ndi grooving zimagawidwa m'mitundu iwiri: zida zodulira ndi grooving. Chida chodulidwacho chimakhala ndi tsamba lalitali komanso lopapatiza. Cholinga cha kapangidwe kameneka ndi kuchepetsa kugwiritsira ntchito zinthu za workpiece ndikuwonetsetsa kuti pakati akhoza kudulidwa pamene kudula.Momwe mungasankhire chida choyenera chodulidwa ndi grooving chingaganizidwe kuchokera kuzinthu zotsatirazi.

1. Dziwani mtundu wa poyambira

Pali mitundu itatu yofunikira yopangira zida zodulira ndi grooving, zomwe ndi ma groove akunja, ma groove amkati ndi ma groove omaliza. Mipope yakunja ndiyosavuta kuyikonza chifukwa mphamvu yokoka ndi zoziziritsa kukhosi zingathandize kuchotsa chip. Kuphatikiza apo, kukonza kwa groove kunja kumawonekera kwa wogwiritsa ntchito, ndipo mawonekedwe opangira amatha kuyang'aniridwa mwachindunji komanso mosavuta. Koma zopinga zina zomwe zingalephereke pakupanga zida zogwirira ntchito kapena kukanikiza ziyeneranso kupewedwa. Nthawi zambiri, kudulidwa kumakhala bwino kwambiri pamene nsonga ya chida cha grooving imasungidwa pang'ono pansi pa mzere wapakati.

Kubowola m'mabowo kuli kofanana ndi kukumba m'mimba mwake, kupatula kuti kugwiritsa ntchito zoziziritsa kukhosi ndi kuchotsa chip kumakhala kovuta kwambiri. Kwa mkati mwa dzenje grooving, ntchito yabwino imatheka pamene nsonga ili pamwamba pa mzere wapakati. Kukonza mapeto a nkhope groove, chidacho chiyenera kusuntha kumbali ya axial, ndipo utali wa kumbuyo kwa chidacho uyenera kufanana ndi utali wa malo opangidwa ndi makina. The Machining zotsatira bwino pamene nsonga ya mapeto nkhope grooving chida ndi apamwamba pang'ono kuposa mzere pakati.

2. Makina opanga zida ndi mikhalidwe yaukadaulo

Pokonza grooving, mtundu wa mapangidwe ndi luso la chida cha makina ndi zinthu zofunika kuziganizira.

Zina mwazofunikira zazikulu zogwirira ntchito chida cha makina ndi: mphamvu zokwanira zowonetsetsa kuti chidacho chikuyenda mkati mwa liwiro lolondola popanda kuyimitsidwa kapena kugwedezeka; kukhazikika kokwanira kuti mutsirize kudula kofunikira popanda kuyankhulana; Kuthamanga kokwanira koziziritsa ndi kutuluka kumathandiza kuchotsa chip; Kuthamanga kokwanira koziziritsa ndi kutuluka kumathandiza kuchotsa chip; kulondola kokwanira. Kuphatikiza apo, ndikofunikiranso kukonza bwino ndikuwongolera chida chamakina kuti muthe kukonza mawonekedwe ndi kukula kwake koyenera.

3. Kumvetsa makhalidwe a workpiece zakuthupi

Kudziwa zina za zida zogwirira ntchito (monga kulimba kwamphamvu, kuuma kwa ntchito ndi kulimba mtima) ndikofunikira kuti mumvetsetse momwe chogwiriracho chimakhudzira chidacho.

Mukakonza zida zosiyanasiyana zogwirira ntchito, ndikofunikira kugwiritsa ntchito liwiro lodulira ndi mawonekedwe a mita kuwongolera tchipisi, kapena kugwiritsa ntchito mita yapadera yafiriji kuti muwonjezere moyo wa chida.

Mwachidule, kusankha kolondola ndi kugwiritsa ntchito zida zodulira kudzatsimikizira mtengo wa kukonza. Zida za Grooving zimatha kupanga geometry ya workpiece m'njira ziwiri: imodzi ndiyo kupanga mawonekedwe onse a groove kupyolera mu kudula kumodzi; chinacho ndi kukulitsa kukula komaliza kwa poyambira pamasitepe kudzera m'mabala angapo. Mukasankha zida za geometry, mutha kuganizira kugwiritsa ntchito zokutira zida zomwe zitha kupititsa patsogolo magwiridwe antchito a chip.