IINDABA zeNKAMPANI

《 ULUHLU NGEMVA

Indlela yokukhetha isixhobo sokusika kunye ne-grooving

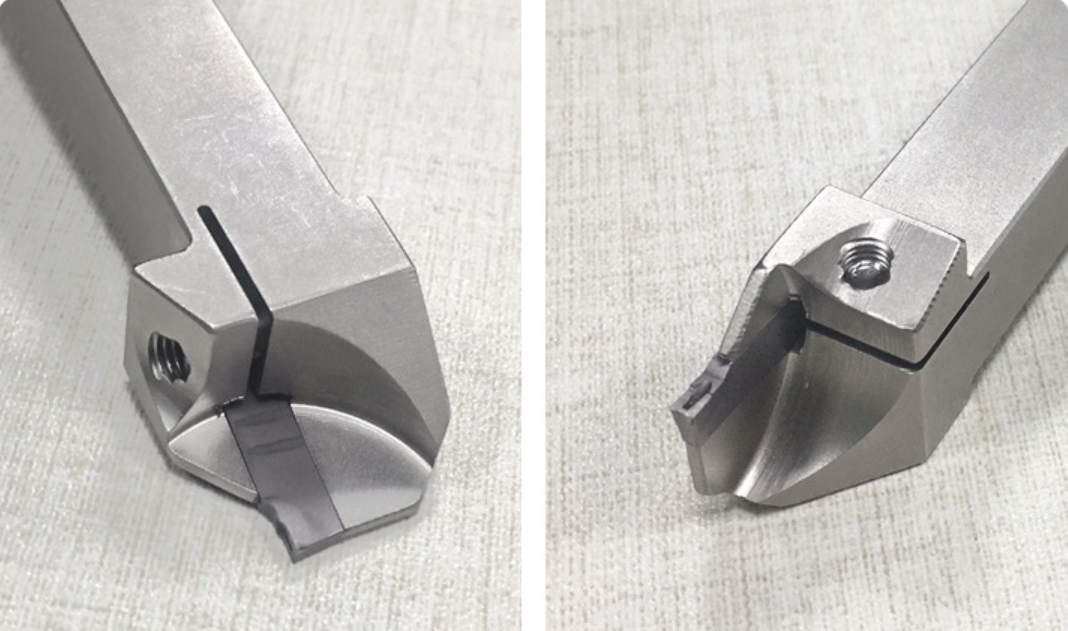

Izixhobo zokusika kunye ne-grooving zihlukaniswe zibe zimbini iintlobo: izixhobo zokusika kunye ne-grooving. Isixhobo esinqunyiweyo sinomgca omde kunye nentsimbi encinci. Injongo yolu qulunqo kukunciphisa ukusetyenziswa kwezinto eziphathekayo kunye nokuqinisekisa ukuba iziko linokunqunyulwa xa lisikwa.Indlela yokukhetha isixhobo esifanelekileyo sokusika kunye ne-grooving sinokuqwalaselwa kule miba ilandelayo.

1. Chonga uhlobo lomsele

Kukho iintlobo ezintathu ezibalulekileyo ze-groove zezixhobo zokusika kunye ne-grooving, eziyi-grooves yangaphandle, i-grooves yangaphakathi kunye ne-grooves ekupheleni. Iigrooves zangaphandle zezona zilula ukusetyenzwa kuba umxhuzulane kunye nokupholisa kunganceda ukususwa kwetshiphu. Ukongezelela, ukuqhutyelwa kwe-groove yangaphandle kubonakala kumqhubi, kwaye umgangatho wokucubungula unokujongwa ngokuthe ngqo kwaye ngokulula. Kodwa eminye imiqobo enokubakho kuyilo lwesixhobo sokusebenza okanye i-clamping nayo kufuneka ithintelwe. Ngokuqhelekileyo, umphumo wokusika ungcono xa incam yesixhobo se-grooving igcinwa kancinane ngaphantsi komgca ophakathi.

Ukukrolwa komngxuma wangaphakathi kuyafana nokukrolwa kwedayamitha yangaphandle, ngaphandle kokuba ukufakwa kwesipholisi kunye nokususwa kwetshiphu kungumngeni. Kwi-grooving ye-hole yangaphakathi, ukusebenza kakuhle kufezekiswa xa incam ingaphezulu kancinane kumgca ophakathi. Ukucutshungulwa kokuphela kobuso begroove, isixhobo kufuneka sikwazi ukuhamba kwicala le-axial, kwaye i-radius yobuso obungasemva besixhobo kufuneka ihambelane neradiyasi yendawo eyenziwe ngomatshini. Isiphumo somatshini singcono xa incam yesixhobo sokujonga ubuso siphezulu kancinci kunomgca osembindini.

2. Uyilo lwesixhobo somatshini kunye neemeko zobugcisa

Kwinkqubo ye-grooving, uhlobo loyilo kunye neemeko zobugcisa zesixhobo somatshini nazo ziyizinto ezisisiseko ekufuneka ziqwalaselwe.

Ezinye zeemfuno eziphambili zokusebenza kwisixhobo somatshini zibandakanya: amandla aneleyo okuqinisekisa ukuba isixhobo sihamba ngaphakathi kwinqanaba elichanekileyo lesantya ngaphandle kokuphazamiseka okanye ukugubha; ukuqina okwaneleyo ukugqiba inkqubo yokusika efunekayo ngaphandle kokuxoxa; uxinzelelo olwaneleyo lokupholisa kunye nokuhamba ukunceda ukususwa kwetshiphu; uxinzelelo olwaneleyo lokupholisa kunye nokuhamba ukunceda ukususwa kwetshiphu; ukuchaneka okwaneleyo. Ukongeza, kukwabalulekile ukulungisa ngokufanelekileyo kwaye ulungelelanise isixhobo somatshini ukuze uqhubekisele phambili ubume begroove kunye nobukhulu obuchanekileyo.

3. Qonda iimpawu zempahla yokusebenza

Ukuqhelana neempawu ezithile zesixhobo sokusebenza (njengokuqina kokuqina, iimpawu zokuqina komsebenzi kunye nokuqina) kubalulekile ekuqondeni ukuba i-workpiece isichaphazela njani isixhobo.

Xa kusetyenzwa izixhobo ezahlukeneyo zokusebenza, kuyimfuneko ukusebenzisa isantya sokusika kunye neemitha zokumila ukulawula iitshiphusi, okanye usebenzise iimitha ezikhethekileyo zesikhenkcisi ukwandisa ubomi besixhobo.

Isishwankathelo, ukhetho oluchanekileyo kunye nokusetyenziswa kwezixhobo zokusika kuya kugqiba iindleko ezisebenzayo zokulungisa. Izixhobo ze-Grooving zinokuvelisa i-geometry ye-workpiece ngeendlela ezimbini: enye kukuvelisa yonke imilo ye-groove nge-cut single; enye kukurhabaxa ubungakanani bokugqibela bomsele ngokwamanyathelo ngokusikeka okuninzi. Emva kokukhetha isixhobo sejometri, unokuqwalasela ukusebenzisa izixhobo zokugquma ezinokuthi ziphucule ukusebenza kwe-chip evacuation.