IZINDABA YENKAMPANI

《 EMUVA UHLU

Indlela yokukhetha ithuluzi lokusika kanye ne-grooving

Amathuluzi okusika kanye ne-grooving ahlukaniswe izinhlobo ezimbili: amathuluzi okusika kanye nama-grooving. Ithuluzi elisikiwe linenkemba ende kanye nensimbi encane. Inhloso yalo mklamo ukunciphisa ukusetshenziswa kwezinto ezibonakalayo ze-workpiece kanye nokuqinisekisa ukuthi isikhungo singanqunywa lapho usikwa.Indlela yokukhetha ithuluzi elifanele lokusika kanye ne-grooving lingacatshangelwa kusukela kulezi zici ezilandelayo.

1. Thola uhlobo lomsele

Kunezinhlobo ezintathu ezibalulekile zemisele yamathuluzi ayisikiwe kanye nama-grooving, okuyimifantu yangaphandle, imifantu yangaphakathi kanye nemisele yokugcina. Imifantu yangaphandle kulula ukuyicubungula ngoba amandla adonsela phansi kanye nokupholisa kungasiza ekukhipheni ama-chip. Ngaphezu kwalokho, ukucubungula kwe-groove yangaphandle kubonakala ku-opharetha, futhi ikhwalithi yokucubungula ingabhekwa ngokuqondile futhi kalula. Kodwa ezinye izithiyo ezingaba khona ekwakhiweni kweziqeshana zokusebenza noma ukubopha kufanele futhi kugwenywe. Ngokuvamile, umphumela wokusika ungcono kakhulu uma ichopho lethuluzi lokugoba ligcinwe ngaphansi kancane komugqa omaphakathi.

I-hole grooving yangaphakathi iyafana nokuvula i-diameter yangaphandle, ngaphandle kokuthi ukusetshenziswa kokupholisa kanye nokususwa kwe-chip kuyinselele kakhulu. Ukuze uthole imbobo yangaphakathi, ukusebenza okuhle kakhulu kufinyelelwa uma ithiphu ingaphezu kancane komugqa omaphakathi. Ukucubungula i-groove yobuso bokuphela, ithuluzi kufanele likwazi ukuhamba libheke ku-axial, futhi i-radius yobuso obungemuva bethuluzi kufanele ihambisane ne-radius yendawo emshinini. Umthelela womshini ungcono kakhulu uma ichopho lethuluzi lokugoqa ubuso bokuphela liphakeme kancane kunomugqa omaphakathi.

2. Ukwakhiwa kwethuluzi lomshini kanye nezimo zobuchwepheshe

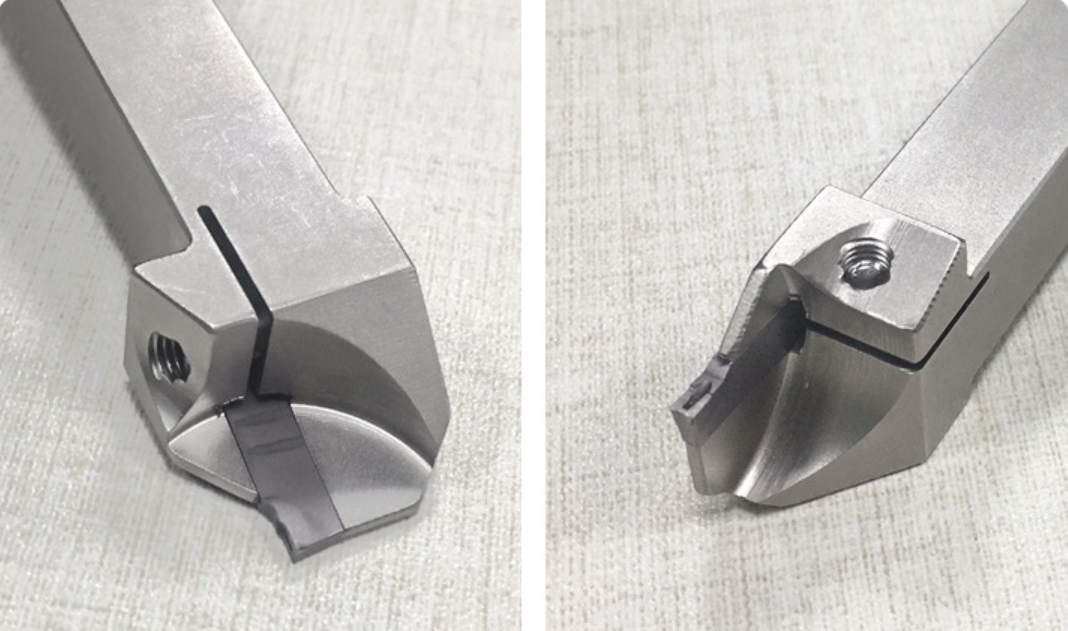

Ekucubunguleni i-grooving, uhlobo lomklamo nezimo zobuchwepheshe zethuluzi lomshini nazo ziyizinto eziyisisekelo okudingeka zicatshangelwe.

Ezinye zezimfuneko zokusebenza eziyinhloko zethuluzi lomshini zihlanganisa: amandla anele okuqinisekisa ukuthi ithuluzi lihamba phakathi kwebanga elifanele lesivinini ngaphandle kokuma noma ukunyakaziswa; ukuqina okwanele ukuqedela inqubo yokusika edingekayo ngaphandle kokuxoxa; ingcindezi eyanele yokupholisa kanye nokugeleza ukusiza ukususwa kwe-chip; ingcindezi eyanele yokupholisa kanye nokugeleza ukusiza ukususwa kwe-chip; ukunemba okwanele. Ngaphezu kwalokho, kubalulekile futhi ukulungisa kahle futhi ulinganise ithuluzi lomshini ukuze ucubungule umumo olungile we-groove nosayizi.

3. Qonda izici ze-workpiece material

Ukujwayelana nezinye izici zezinto zokusebenza (njengamandla aqinile, izici eziqinisa umsebenzi kanye nokuqina) kubalulekile ukuze uqonde ukuthi ucezu lokusebenza lulithinta kanjani ithuluzi.

Lapho ucubungula izinto ezisetshenziswayo ezahlukahlukene, kuyadingeka ukusebenzisa isivinini sokusika kanye namamitha wokuma ukuze ulawule ama-chips, noma usebenzise amamitha efriji akhethekile ukuze welule impilo yamathuluzi.

Kafushane, ukukhetha okulungile nokusetshenziswa kwamathuluzi okusika kuzonquma ukusebenza kahle kwezindleko zokucubungula. Amathuluzi e-Grooving angakhiqiza i-geometry ye-workpiece ngezindlela ezimbili: eyodwa ukukhiqiza yonke i-groove shape ngokusebenzisa ukusika okukodwa; enye iwukuba usayizi wokugcina we-groove ngezinyathelo ngokusebenzisa ukusikeka okuningi. Ngemva kokukhetha i-geometry yethuluzi, ungacabangela ukusebenzisa izembozo zethuluzi ezingathuthukisa ukusebenza kokuphuma kwe-chip.