- Mon - Sun:0:00-24:00

- 24/7 Customer Support

- +86 181 1879 8239

- info@eathtools.com

- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

BLOG

BLOG

-

Explore the relationship between the size of the back angle and the life of the insert

The size of the front angle of the carbide blade will affect the change of cutting resistance, and it will also affect the generation of cutting heat. 2024-09-05 Read More

-

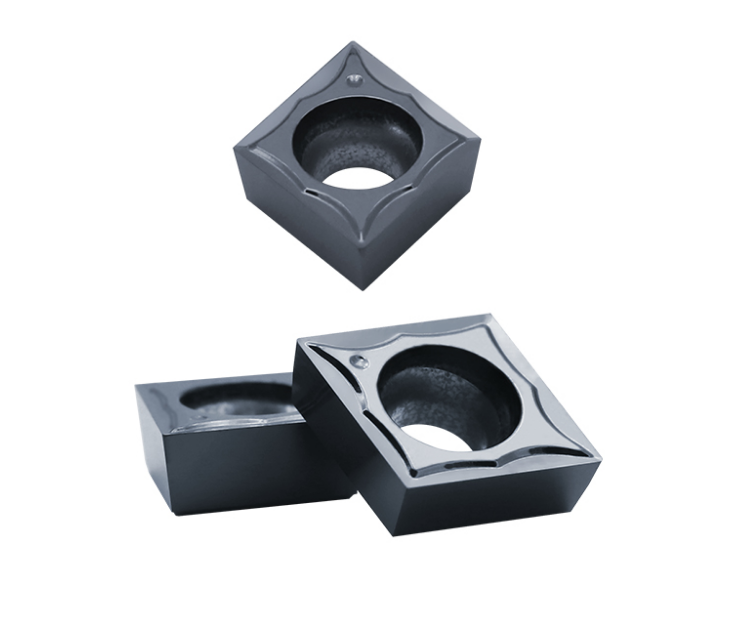

What is a Swiss lathe blade?

Swiss lathe blade, also known as a small parts blade, is a high-precision, high-efficiency machine tool processing tool. It is widely used in various high-efficiency CNC machining machines and is suitable for semi-finishing and finishing of stainless steel, steel parts, easy-to-turn iron and cast iron. 2024-08-20 Read More

-

How to choose end mills

End mills are the most commonly used milling cutters on CNC machine tools. There are cutting blades on the cylindrical surface and end face of the end mill. They can cut at the same time or separately. They are mainly used for plane milling, groove milling, step face milling and profile milling. They are divided into integral end mills and brazed end mills. 2024-08-15 Read More

-

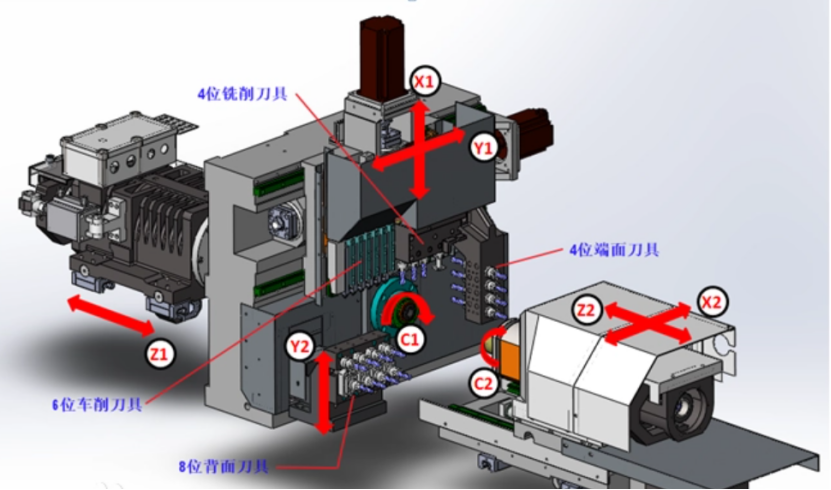

Swiss-type lathes and Swiss-type lathe inserts

Swiss-type lathe is called Swiss-type CNC lathe. It is a precision processing equipment that can complete complex processing such as turning, milling, drilling, boring, tapping, and engraving at the same time. It is mainly used for batch processing of precision hardware and shaft-type non-standard parts. 2024-08-07 Read More

-

Cemented Carbide Materials and Industry Analysis

As the "teeth of industry", cemented carbide is widely used in military industry, aerospace, mechanical processing, metallurgy, oil drilling, mining tools, electronic communications, construction and other fields. With the development of downstream industries, the market demand for cemented carbide continues to increase. In the future, the manufacturing of high-tech weapons and equipment, the progress of cutting-edge science and technology, and the rapid development of nuclear energy will greatly increase the demand for cemented carbide products with high technology content and high quality stability. Cemented carbide can also be used to make rock drilling tools, mining tools, drilling tools, measuring tools, metal grinding tools, precision bearings, nozzles, hardware molds, etc. 2024-08-01 Read More

-

How to choose a cutting and grooving tool

Cut-off and grooving tools are divided into two types: cut-off and grooving tools. The cut-off tool has a longer blade and a narrow blade. The purpose of this design is to reduce the material consumption of the workpiece and ensure that the center can be cut when cutting. 2024-07-25 Read More

-

10 Common Problems and Solutions for Deep Hole Processing

In the process of machining, we will encounter various problems. If we do not solve them in time, it will not only affect the processing progress and product quality, but also cause damage to the machine tool. Today we will discuss 10 common problems and solutions in reamer processing. 2024-07-15 Read More

-

China's latest tungsten powder price

China's tungsten price is temporarily stable, and the overall market is still in a downward cycle. 2024-06-11 Read More

-

Tool damage and coping strategies

EATH TOOLS mainly produces CNC blades, turning discard tool bars, high-speed steel tool bars, tungsten steel anti-vibration tool bars, tungsten steel thread tool bars, carbide milling cutters, ball cutters, nose cutters, drill bits, reamers, non-standard products, etc. 2024-06-07 Read More

-

How are carbide indexable CNC inserts produced?

How are carbide indexable CNC inserts produced? 2024-06-03 Read More