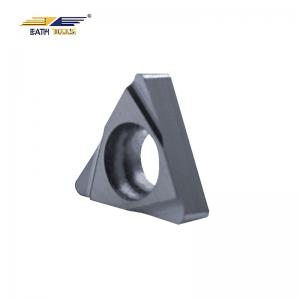

āhuatanga hua:

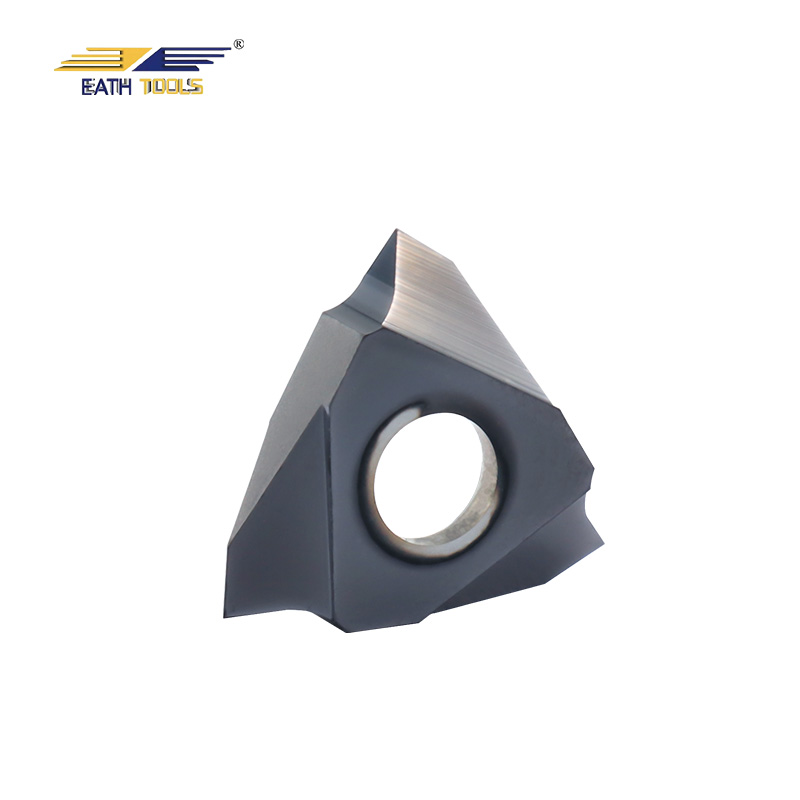

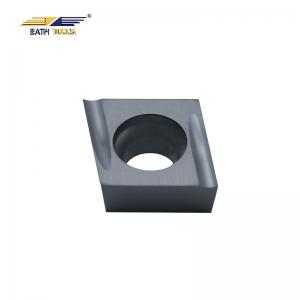

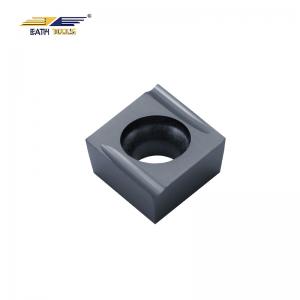

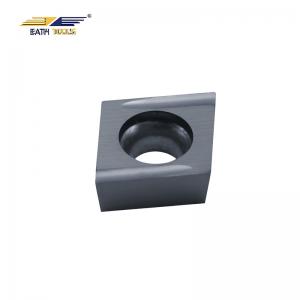

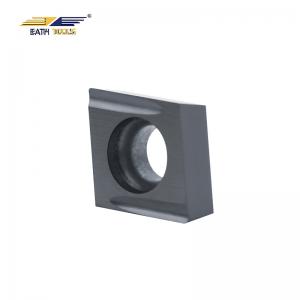

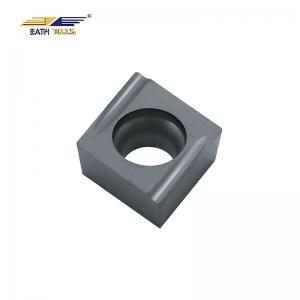

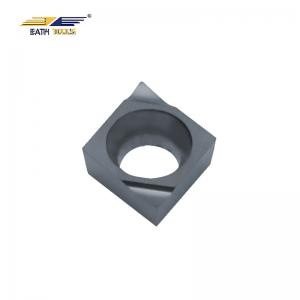

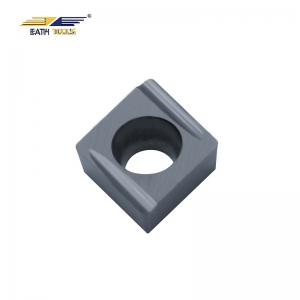

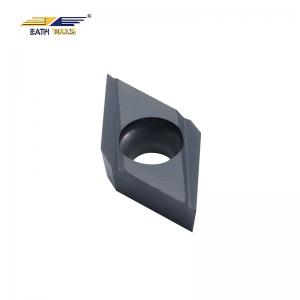

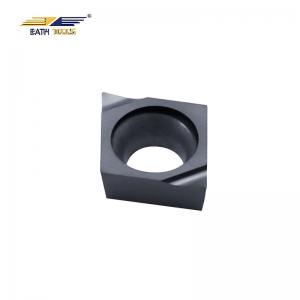

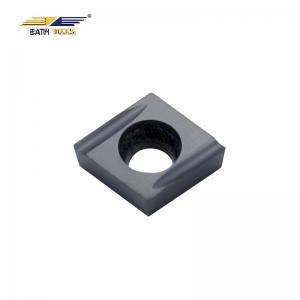

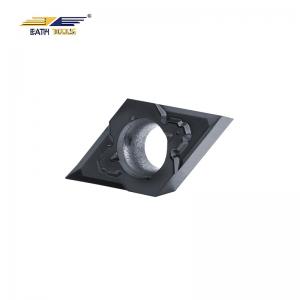

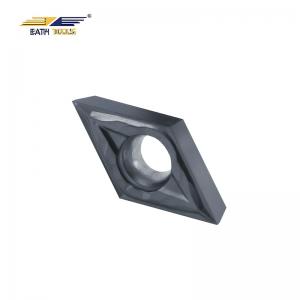

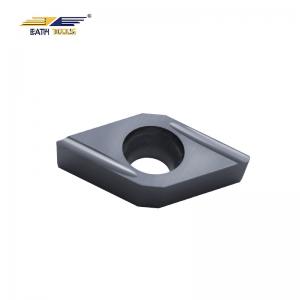

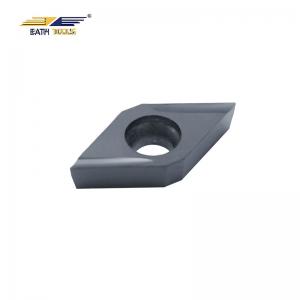

1. 100% original carbide powder and excellent wear resistance and toughness;

2. Te mahi teitei o te paninga CVD / PVD, me te tino pakeke me te maeneene o te mata;

3. ISO9001:2015 quality system control;

4. Te hoahoa maramara-breaker ngaio me te whakarato i te mahi tapahi tino pai;

5. Te rahinga tika, te kounga teitei, te utu whakataetae;

6.Super roa te ora ratonga taputapu;

7. Ko te hoahoa whakauru kua whakaritea, te whakakikorua, te tohu, te putea kei te wātea.

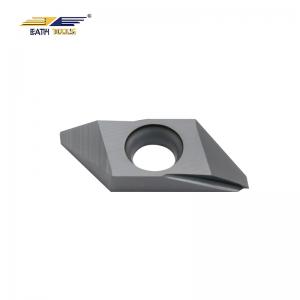

Āhuatanga Hua:

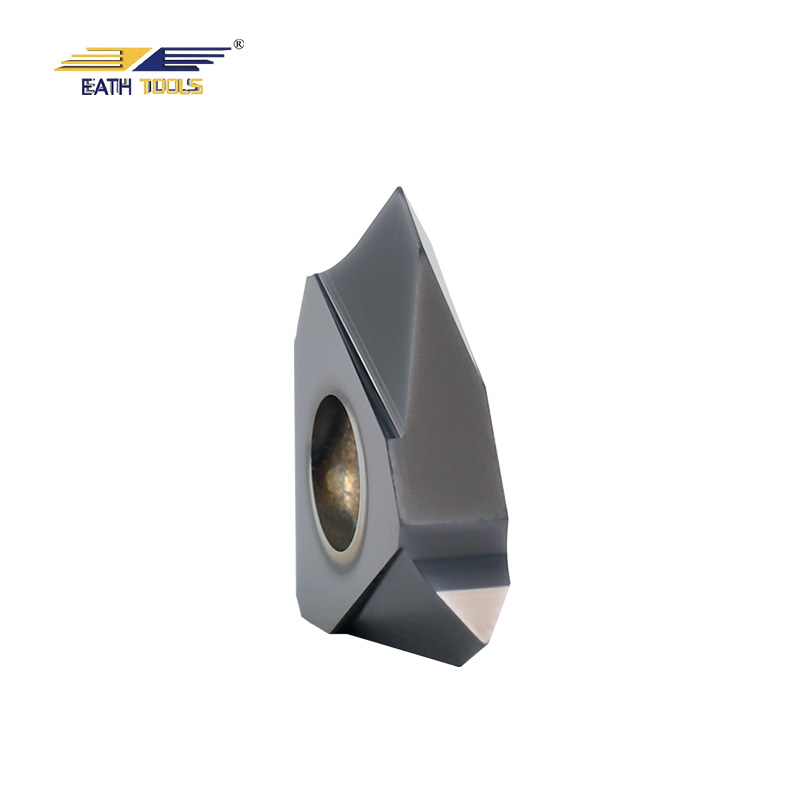

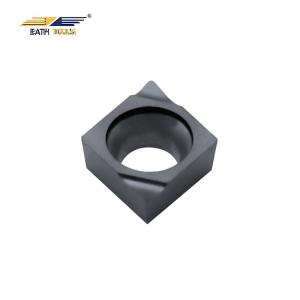

1. 100% original carbide powder and excellent wear resistance and toughness;

2.

3. ISO9001:2015 quality system control;

4. Hoahoa maramara maramara ngaio me te whakarato i nga mahi tapahi tino tika;

5.. Te kiko tika, te kounga nui, te utu whakataetae;

6. Te ratonga ratonga roa;

7. Ko te hoahoa whakauru whakaurunga, paninga, tohu, me te kapi e waatea ana.

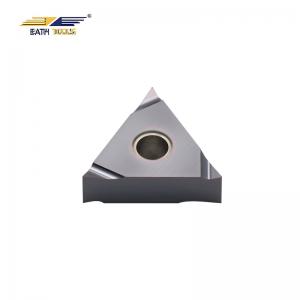

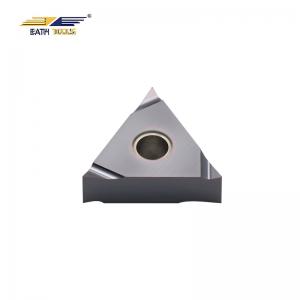

| Tuhinga | Patupatu (mm) | Whakauruhia nga waahanga (MM) | Koki | Kaihanga maramara maramara | |||

| IC | S | D | R | ||||

| 16ER/L 050ISO | 0.5 | 9.525 | 3.68 | 4.0 | 0.06 | 60° | / |

| 16ER/L 075ISO | 0.75 | 9.525 | 3.68 | 4.0 | 0.09 | 60° | / |

| 16ER/L 100ISO | 1.0 | 9.525 | 3.68 | 4.0 | 0.12 | 60° | / |

| 16ER/L 125ISO | 1.25 | 9.525 | 3.68 | 4.0 | 0.15 | 60° | / |

| 16ER/L 150ISO | 1.5 | 9.525 | 3.68 | 4.0 | 0.19 | 60° | / |

| 16ER/L 175ISO | 1.75 | 9.525 | 3.68 | 4.0 | 0.22 | 60° | / |

| 16ER/L 200ISO | 2.0 | 9.525 | 3.68 | 4.0 | 0.25 | 60° | / |

| 16ER/L 250ISO | 2.5 | 9.525 | 3.68 | 4.0 | 0.32 | 60° | / |

| 22ER 300ISO | 3.0 | 12.7 | 4.9 | 4.85 | 0.41 | 60° | / |

| 22ER 350ISO | 3.5 | 12.7 | 4.9 | 4.85 | 0.48 | 60° | / |

| 22ER 400ISO | 4.0 | 12.7 | 4.9 | 4.85 | 0.55 | 60° | / |

| 22ER 450ISO | 4.5 | 12.7 | 4.9 | 4.85 | 0.62 | 60° | / |

| 22ER 500ISO | 5.0 | 12.7 | 4.9 | 4.85 | 0.70 | 60° | / |

| TTX32R 6000 | 0.5-1.0 | 9.525 | 3.18 | 4.4 | 0.00 | 60° | / |

| TTX32R 6005 | 0.5-1.0 | 9.525 | 3.18 | 4.4 | 0.05 | 60° | / |

| TTX32R 6001 | 1.0-2.0 | 9.525 | 3.18 | 4.4 | 0.1 | 60° | / |

| TTX32R 6000S | 0.5- | 9.525 | 3.18 | 4.4 | 0 | 60° | / |

| TTX32R 6005S | 0.5- | 9.525 | 3.18 | 4.4 | 0.05 | 60° | / |

| TTX32R 5501 | _ | 9.525 | 3.18 | 4.4 | 0.1 | 55° | / |

| TTX32R 5501S | _ | 9.525 | 3.18 | 4.4 | 0.15 | 55° | / |

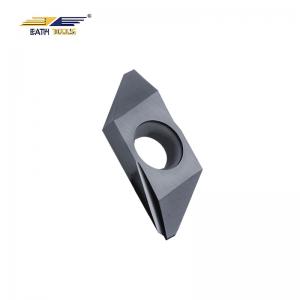

Ngahere mo te whakamahi:

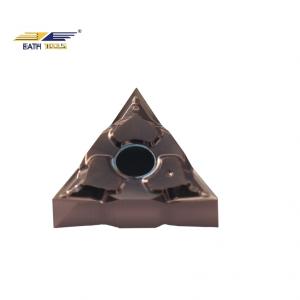

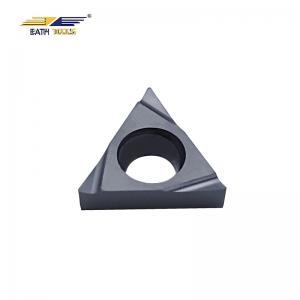

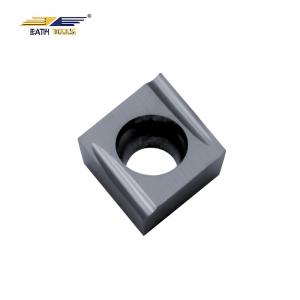

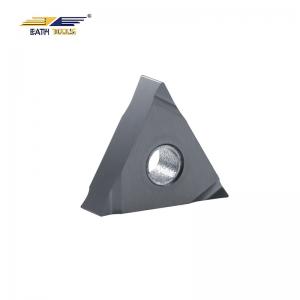

1. Whiriwhiria te maara e tika ana i runga i te momo o te tikanga e whakahaerehia ana.

2. Tīpakohia te rauemi whakauru me te whakauru i te papakupu i runga i nga tikanga tapahi.

3. Whiriwhiria he koikoi me te tino pai me te pumau.

4. Ko te Geometry o te Whakauru he mana nui ki te tapahi me te iti o te kounga.

5. Ka taea e te paninga pani te whakapai ake i te uaua, te kakahu, te waikawa

Haerenga wheketere

FAQ:

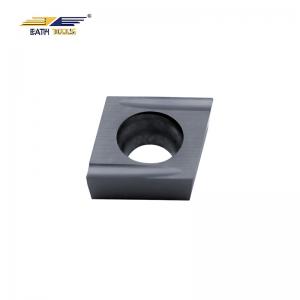

1. He aha o hua matua?

Ko nga Utauta Eath te nuinga o te hanga i nga hiu taputapu hurihuri o waho, nga taputapu hurihuri o roto, nga kopae tapahi mira, nga whao me te miro taputapu, nga whakauru tungsten carbide, me nga taputapu iti.

2. Me pehea te wa tuku?

I te nuinga o te waa, kei a matou he taonga mo nga rahi paerewa, mena kaore he taonga, ko to matou wa tuku kei roto i nga ra 15.

3. He kamupene hokohoko koe, he wheketere ranei?

He kaihanga ngaio matou mo nga tau 15 neke atu.

________________________________________________________________________________________________________________________

Shenzhen Yiteng Cutting Tools Co., Ltd.

Wāhi noho: Whare 5, Baohu Industrial Park, Guangpei Community, Guanlan Street, Longhua District, Shenzhen City, Guangdong Province, China

Phone:+86 138 7415 0655

Īmēra:info@eathtools.com

Whatsapp/Wechat:+86 138 7415 0655